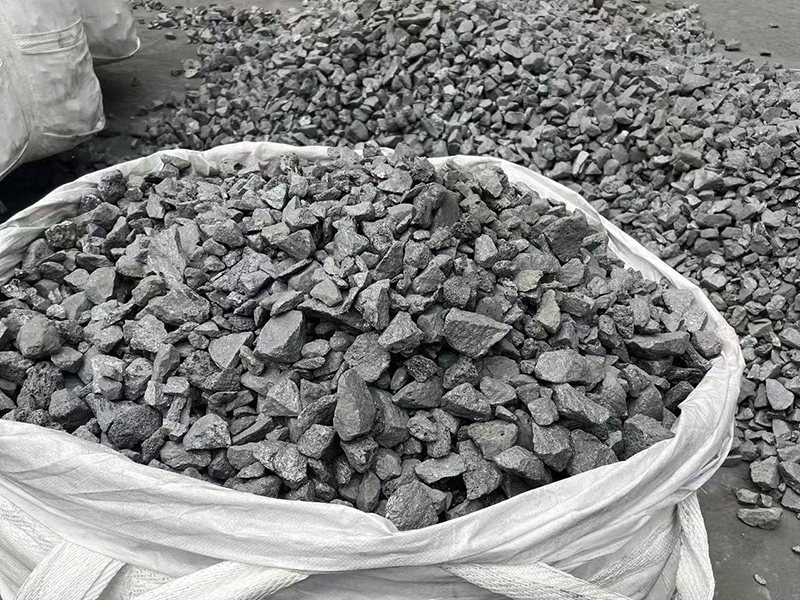

Ferro Silicon is used as an essential alloy in the production of steel and cast iron. Ferro Silicon is used to remove oxygen from

steel and as alloying element to improve the final quality of the steel. Ferro Silicon can also be the basis for manufacture of

pre-alloys like Magnesium Ferro Silicon (FeSiMg), used for modification of melted malleable iron.

Main markets are the worldwide producers of alloyed, stainless and carbon steel. One of the fastest growing categories within

steel is the stainless sector, in both flat and long products. Stainless steel has a specific consumption of Ferro Silicon 5–10 times

higher than regular carbon steel.

Special Ferro Silicon grades, like low Al, High Purity and low C Ferro Silicon, are used in the production of special steel qualities.

Compared to regular Ferro Silicon, special grades of Ferro Silicon will help to keep both the content of inclusions and the carbon

content in the final steel at very low levels.

Ferro Silicon is produced in submerged arc furnaces, using as raw material high-purity quartz, charcoal and iron ore.