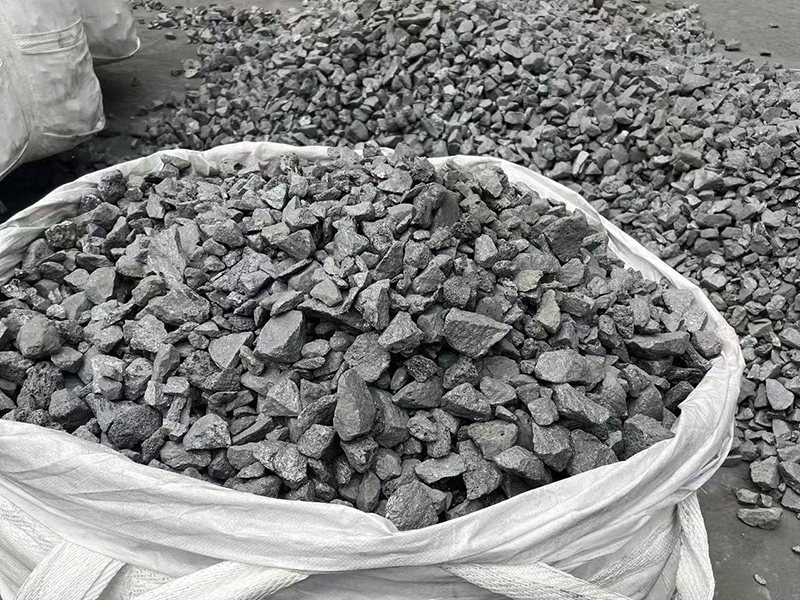

Faced problem: Nowadays, the steelmaking industry firm modify the molten steel content slightly by alloying, used carburant

slightly to change the carbon content. When the molten steel is peroxidation and antioxidant status:

1.Carburant with less density, may caused dow absorption rate, reproducibility is bad, lead to the carbon in molten steel with low hit ratio.

2.Small specific gravity, can’t sink into the molten steel, the reaction interface is small, only limited to the above part or the

surface, and the recovery rate is obviously down. There are many steel- making factory replaced it by carbon cored wire,

but increased the cost, need use special equipment, and operation is complex.Resolve problem: With the development of

steel-making firm, in order to resolve the above shortage, we developed a new and high efficient steelmaking alloy increase

silicon carbon addition silicon carbon alloy.